magtec GmbH

Bahnstrasse 73

67518 Ellerstadt, DE

coating solutions

coating solutions

MagTec GmbH located in Ellerstadt near Ludwigshafen, Germany, is based on fifteen years of unique experience in the field of custom PVD-coating by magnetron sputtering technologies under clean room conditions.

Our specialists offer a broad coating knowhow in various fields of science and technology in the areas of optics and semiconductor industry, space and vacuum technology und neutron physics.

Our techniques include DC-, RF- and reactive magnetron sputtering of a large variety of materials on different substrates including glass, metal (-foils) and silicon wafers surfaces.

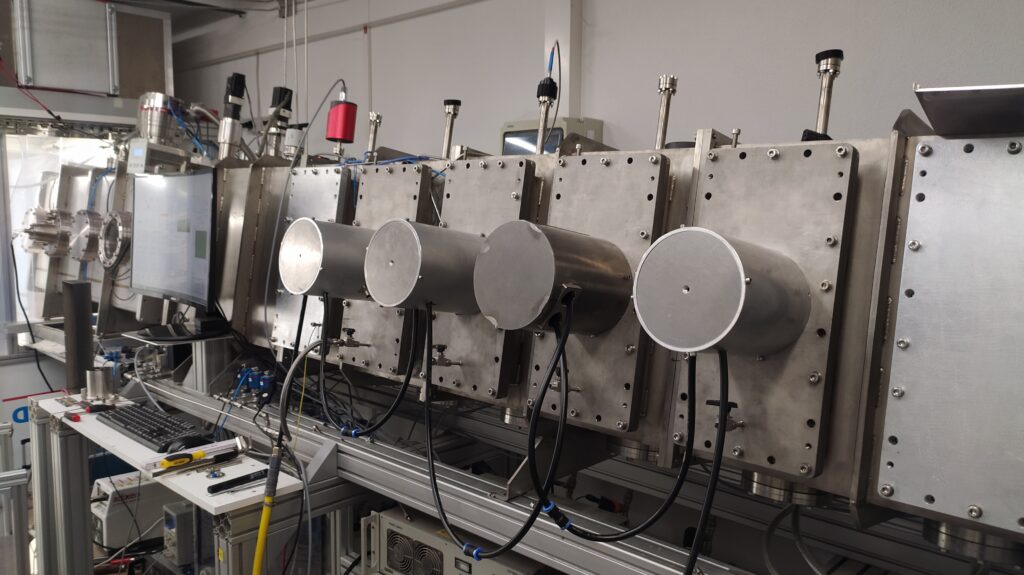

We operate 4 PVD coating systems on a production area of 150 m²:

A mechanical workshop on 100 m² for turning and milling as well as electroerosion offers extensive possibilities in tool and masks construction for coating application or all types of prototyping.

We are experts in magnetic field simulations and design, construct and manufacture customized magnetron sputter sources.

Coating analysis technologies like XRD, XRR, GID and transmission/reflectivity measurements are used in our lab.